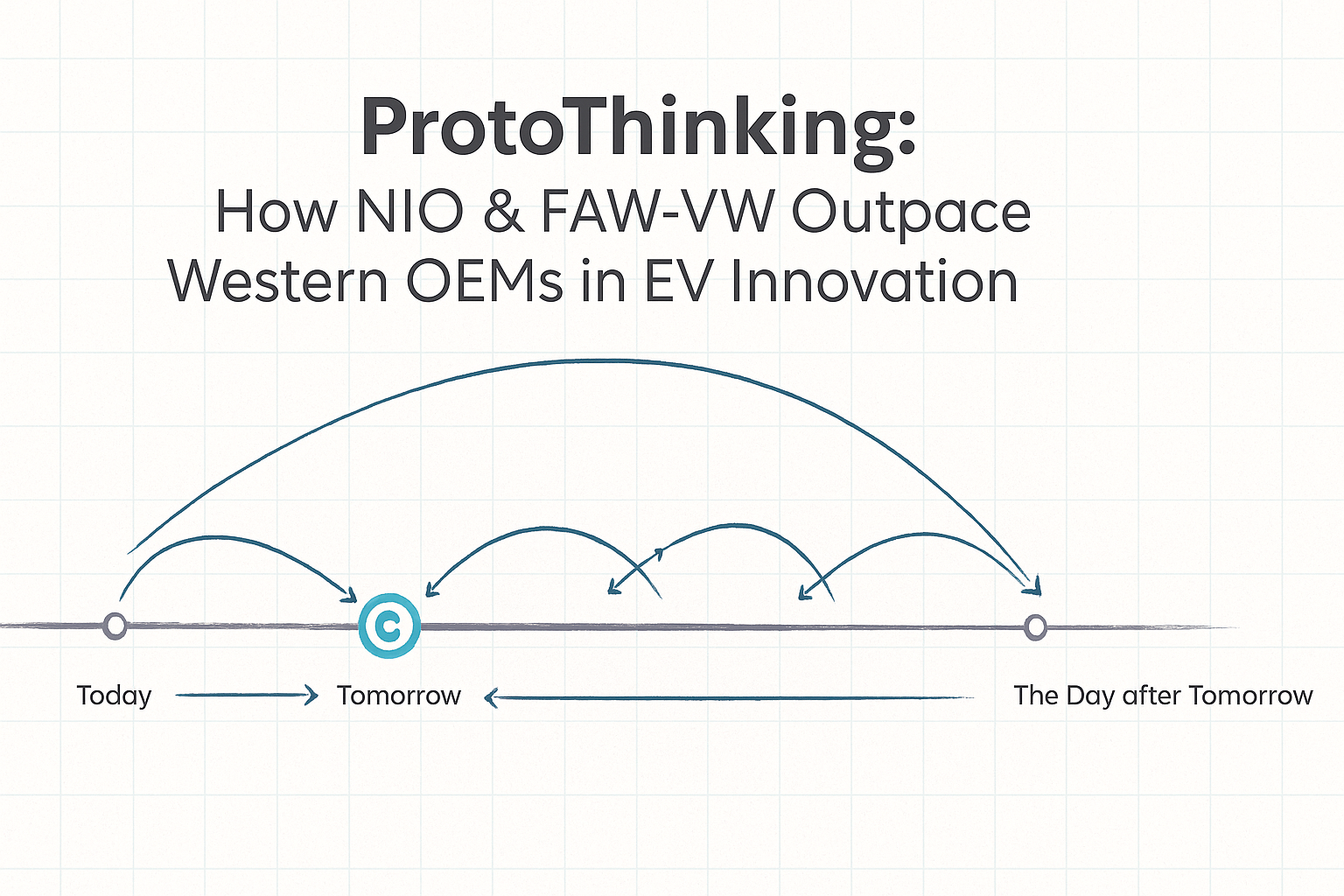

ProtoThinking: How NIO & FAW-VW Outpace Western OEMs in EV Innovation

Why European and American OEMs Must Learn from China's EV Innovation Playbook

The competitive gap isn't just widening, it's fundamentally changing the rules of automotive innovation.

The Chinese automotive market has evolved from a manufacturing hub to a global innovation laboratory. While Western OEMs navigate five-year development cycles, Chinese manufacturers iterate at the speed of consumer technology, releasing updates monthly and launching features that redefine user expectations.

For European and American automotive leaders, this represents a strategic inflection point that demands a fundamental shift in how you approach product development.

The Strategic Imperative: From Validation to Exploration

Traditional automotive development treats prototyping as a checkpoint, a final validation before committing to production. This mindset worked when product cycles aligned with market stability.

That era is over.

Today's market demands ProtoThinking: a methodology that treats prototyping as continuous exploration rather than one-time validation. Companies practicing ProtoThinking don't just move faster; they discover breakthrough solutions that validation-focused competitors never find.

Traditional: "We prototype to validate our designs."

- Goal: Final checkpoint before development

- Outcome: Proving predetermined solutions

ProtoThinking: "We prototype to explore all possibilities."

- Goal: Starting point for innovation

- Outcome: Discovering unknown opportunities and learning through iterative building

In complex, multi-modal environments where experience spans software, hardware, and AI, exploration uncovers possibilities that abstract planning cannot anticipate.

Real-World Impact: Chinese OEMs Leading the Way

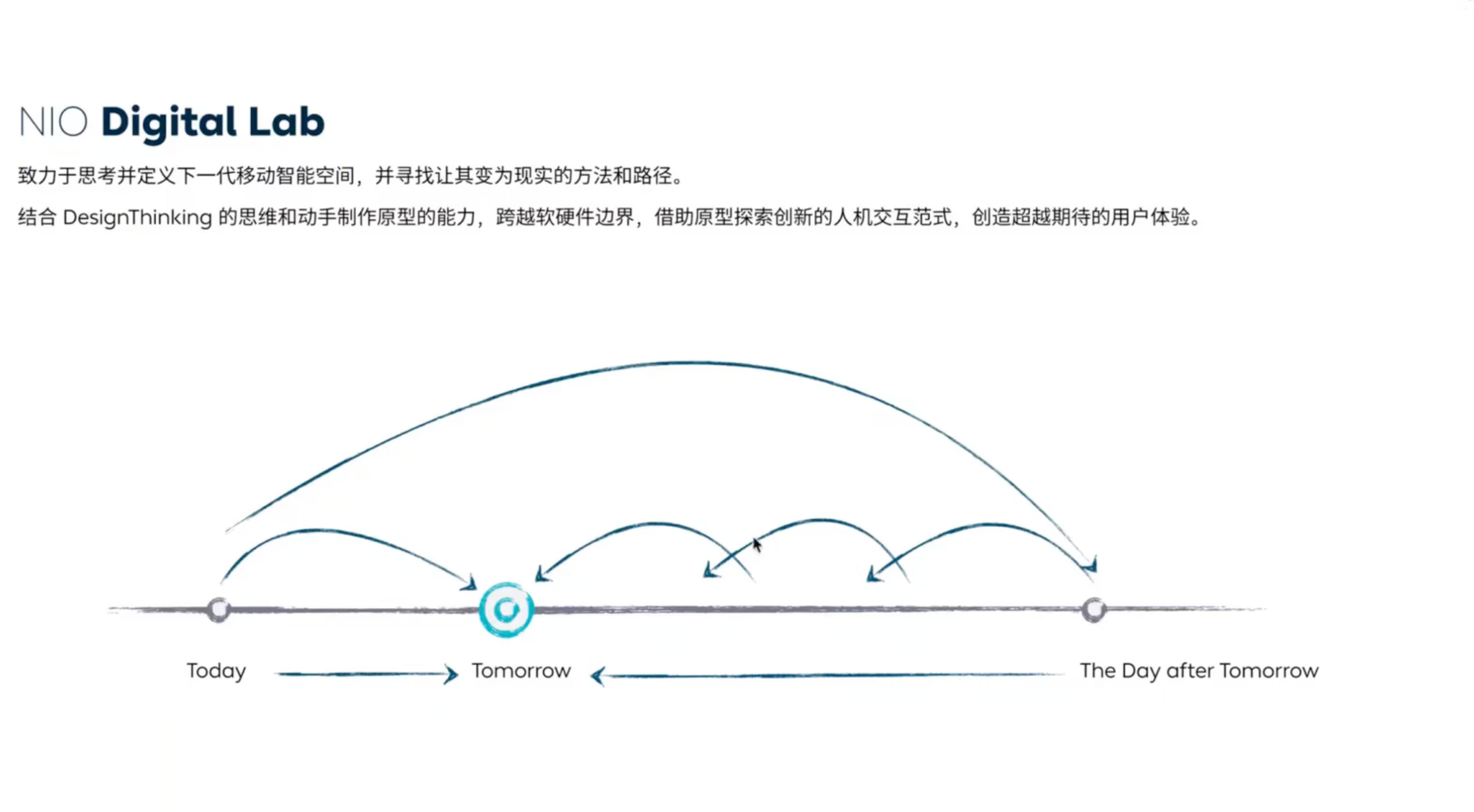

NIO: Designing for Today and Tomorrow Simultaneously

NIO's Digital Lab faces a unique challenge: designing next-generation smart cockpits while preparing for an autonomous future 5-10 years away. Their solution demonstrates ProtoThinking in action through two parallel workstreams:

- Today -> Tomorrow: Projecting current technology forward.

- Distant Future -> Today: Reverse-engineering from autonomous scenarios.

Why ProtoPie Enables This Approach:

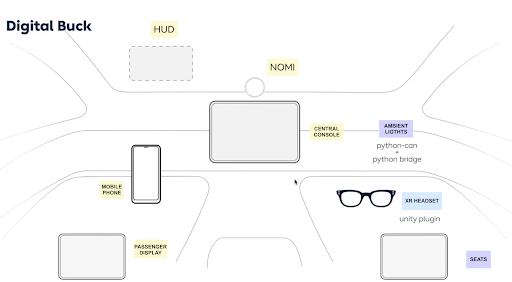

ProtoPie bridges abstract concepts and tangible experiences, allowing designers without coding backgrounds to build complex prototypes integrating:

- Multiple Screens: Instrument clusters, center displays, Head-Up Displays (HUD).

- Physical Hardware: Seats, ambient lighting, NOMI robot.

- Advanced Technologies: LLM APIs, Python Bridge for automotive protocols.

Innovation Through Creative Problem-Solving:

When NIO needed to prototype steering wheel interactions, traditional approaches would require months. Instead, they attached an Apple TV remote to the steering wheel and connected it via Bluetooth to ProtoPie.

Result: Fully functional prototype in under one hour.

AI-Powered Personalization:

NIO's LLM API integration enables natural interactions like: "Hey NOMI, give me cyberpunk ambient lighting." The system converts speech to text, processes through an LLM, returns JSON color parameters, and adjusts physical cabin lighting in real-time, setting a new experience benchmark.

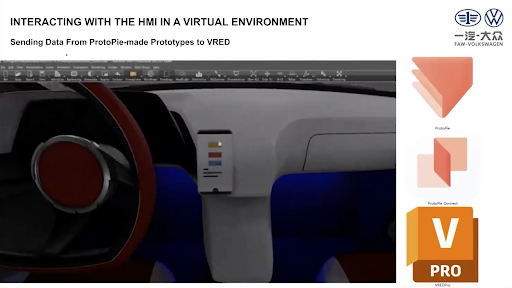

FAW-Volkswagen: VR Validation at Scale

The Challenge: Validate complex HMI designs without the time and cost of physical mockups for every iteration.

The Solution: Integrating ProtoPie Connect with VRED visualization software creates a complete virtual validation environment. Designers can:

- Build full HMI flows in ProtoPie.

- Experience them in VR with real-world fidelity.

- Test visibility from actual driving positions.

- Discover issues like gauge blockage or font legibility before physical development.

Quantifiable Impact:

- Validation Speed: Increased by 80%, transforming a validation process that previously took weeks into same-day review cycles.

- Cost Reduction: Achieved a 90%+ reduction in physical mockup costs, avoiding expenses that often run into the hundreds of thousands of dollars per iteration.

- Issue Discovery: Realized 10x cost avoidance by shifting critical issue discovery (like gauge blockage or font legibility) from expensive late-stage development to low-cost early-stage virtual testing.

The Workflow Transformation

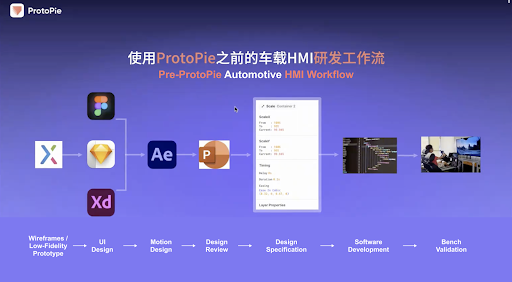

Before ProtoPie

Traditional workflows fragment the design process across multiple tools, rely on static presentations (like PowerPoint) for reviews, and, critically, discover issues only when fixes are most expensive (in the coding or late-testing phase).

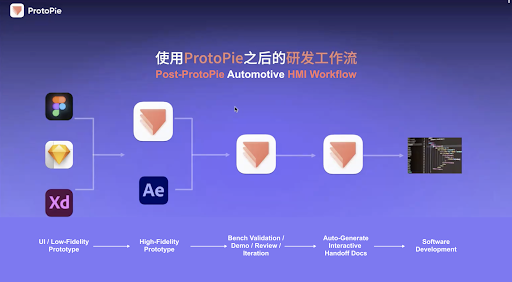

After ProtoPie

ProtoPie consolidates the workflow: import designs with one click, build complex interactions natively, test on real hardware immediately, and auto-generate handoff specs, eliminating communication gaps and enabling rapid, continuous iteration.

Why This Matters for Western OEMs

The Competitive Reality

Chinese EV manufacturers aren't just moving faster, they're building institutional capabilities around rapid exploration and learning. While Western OEMs optimize validation, Chinese competitors optimize learning velocity. This creates a compounding advantage that quickly becomes a strategic moat.

The Technology Gap

When your validation process takes months, you cannot compete with manufacturers releasing updates monthly. ProtoPie bridges this gap through:

- Designer Autonomy: Non-technical teams build complex prototypes independently.

- Hardware Integration: Seamless connection between screens, physical devices, and automotive protocols.

- Advanced Capabilities: Direct support for LLM APIs, Python Bridge, and VR/XR platforms.

- Rapid Iteration: Same-day testing versus weeks of waiting.

Your Path Forward: Adopting ProtoThinking

Adopting ProtoThinking doesn't require abandoning existing processes; it requires augmenting them with exploration capabilities:

Shift Mindset

- Stop: "We need to prove this works."

- Start: "What else could we discover?"

- Start Exploring

- Import designs -> Build alternatives simultaneously -> Test in immersive scenarios.

- Integrate Deeply

- Connect hardware -> Enable team-wide exploration -> Build signal systems for collaboration.

The Business Case

Adopting a ProtoThinking framework yields a superior return on investment (ROI) compared to traditional processes:

- Time to Market: Shifts the product cycle from rigid 5-year cycles to 2-3 years plus continuous updates, accelerating feature release.

- Late-Stage Changes: Achieves a 90% reduction in the most costly changes, avoiding expenses that typically range from $500K to $2M for fixes discovered late in development.

- Innovation Rate: Moves beyond innovation that occurs per generation to a model of continuous releases, ensuring the product remains competitive year-round.

The New Standard

Chinese automotive manufacturers are winning because they've built capabilities around rapid exploration and learning. ProtoThinking, enabled by ProtoPie, makes this possible.

The question isn't whether to adopt these approaches; it's whether you'll adopt them proactively or reactively, and how much market position you're willing to concede while you decide.

Ready to explore like NIO and FAW-Volkswagen?

📧 Contact our sales team to book a demo.

.jpeg)